- Raw Material Preparation

- Compounding

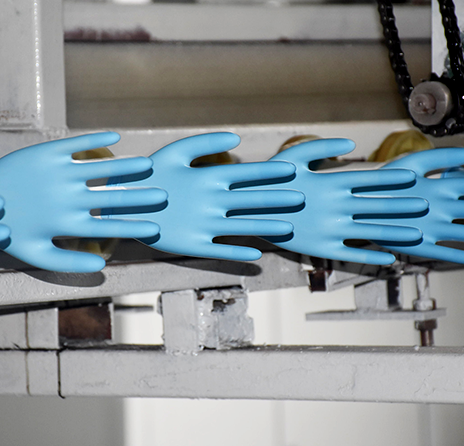

- Dipping Process

- Drying and Vulcanization

- Online Chlorination

- Cooling and Demolding

- Inspection and Sorting

- Finished Product Inspection

- Warehousing and Distribution

NBR Latex

Raw Material Preparation

1

Raw Material Preparation

The main raw material of nitrile gloves is nitrile rubber emulsion. Nitrile rubber is a synthetic rubber formed from a copolymer of acrylonitrile and butadiene. Nitrile rubber emulsion is a white liquid with viscous properties. In nitrile rubber emulsions, it is usually necessary to add some auxiliary materials to improve the performance and characteristics of the gloves. These auxiliary materials may include vulcanizing agents, accelerators, stabilizers, fillers, plasticizers and pigments.

Compounding

2

Compounding

Dipping Process

3

Dipping Process

Drying and Vulcanization

4

Drying and Vulcanization

Online Chlorination

5

Cooling and Demolding

6

Cooling and Demolding

After vulcanization is complete, the gloves are placed together with the mold in a designated cooling area. This is to allow the glove to cool down and maintain its shape. The cooling time is usually based on the size and thickness of the glove and the amount of heat generated during the vulcanization process. After the glove has completely cooled, the mold is opened and the glove is removed from the mold. This can be done manually or automatically, depending on the production equipment and process. The removed gloves will be inspected for release. This includes checking the integrity, appearance and quality of the gloves. If a glove is found to be defective or does not meet standard requirements, it may need to be repaired or deemed defective.

Inspection and Sorting

7

Inspection and Sorting

The inspection and sorting of nitrile gloves is an important step to ensure that product quality meets standards. Strict inspection will be carried out on the appearance, size, strength test, leakage test, component analysis, sorting and grading, packaging and labeling of the gloves to ensure that the nitrile gloves The quality of the gloves meets standard requirements and provides reliable protection.

Finished Product Inspection

8

Warehousing and Distribution

9

Nitrile Gloves

-

NITRILE MEDICAL GLOVESNitrile medical gloves are a type of disposable glove commonly used in healthcare settings to protect healthcare professionals and patients from the spread of infection or contamination. They are made from synthetic rubber and provide excellent puncture resistance and barrier protection against various chemicals, viruses, and bacteria. They are commonly used during examinations, surgeries, and other healthcare activities that require direct contact with bodily fluids, blood, or potentially infectious materials.Explore more

-

NITRILE PROTECTIVE GLOVESNitrile protective gloves are disposable, latex-free gloves made from a synthetic rubber material known as nitrile. They offer exceptional chemical resistance, durability, and tactile sensitivity, making them ideal for various applications, including healthcare, laboratory work, industrial settings, and food handling, where protection against contaminants and allergies is essential.Explore more

-

SPECIAL NITRILE GLOVESSpecialty nitrile gloves are advanced nitrile gloves designed and manufactured to meet the needs of specific industries, work tasks, or special environments. They have special properties and features to provide a higher level of protection and adaptability.Explore more

Interpretation of Made in China

FOCUSED ON NITRILE GLOVES

INDUSTRY FOR MORE THAN 20 YEARS

EN455, 6N, 6319 medical nitrile gloves manufacturers and factory

, The products are widely used in medical, food, electronics, catering, household, etc.-

0YEAR

CORPORATE HISTORY

-

0m²

FACTORY AREA

-

0BILLION

ANNUAL PRODUCTION CAPACITY

-

0+

EXPORTING COUNTRY

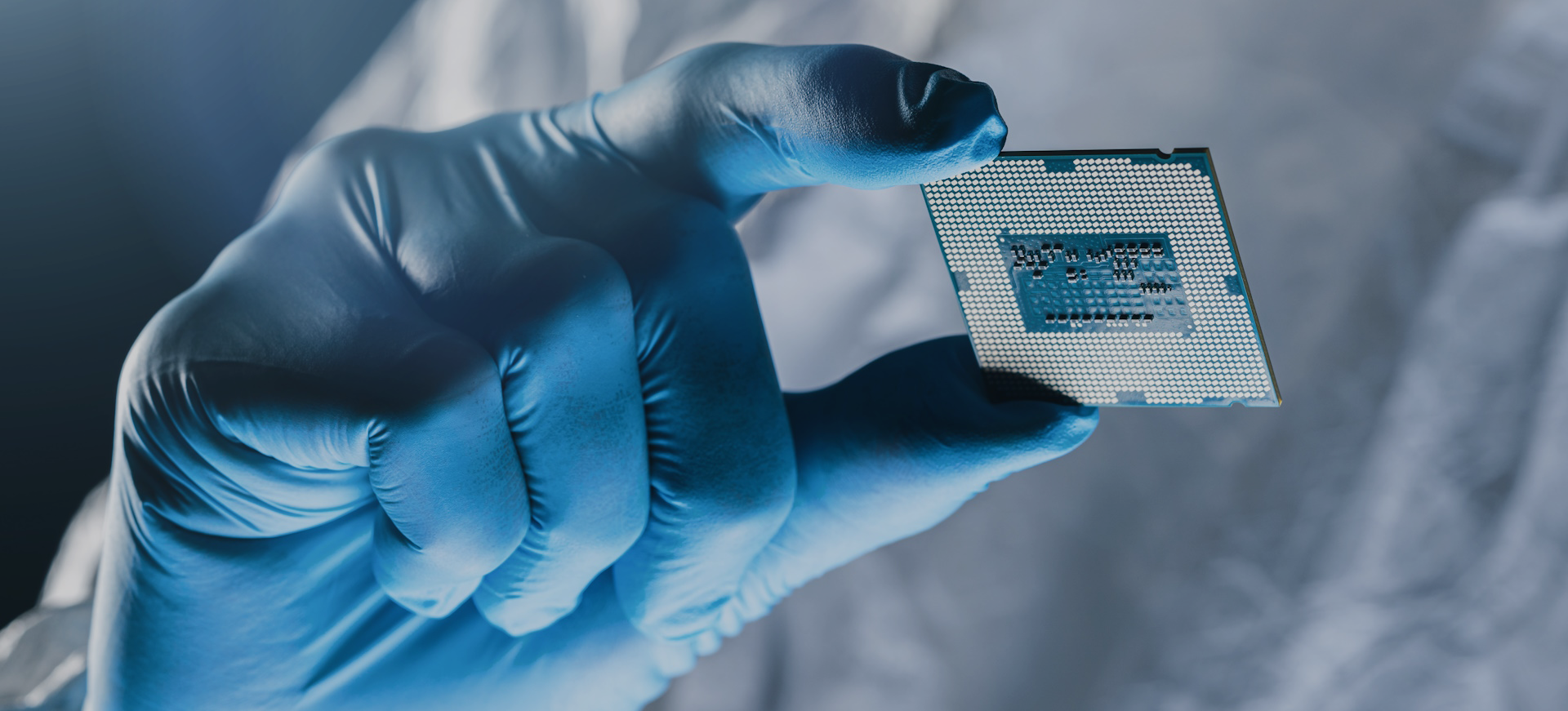

Nitrile gloves play an important role in the semiconductor industry, providing protection against sensitive materials, chemicals and static electricity while ensuring operator safety. When selecting and using nitrile gloves, the selection should be based on specific process requirements and safety regulations to ensure that the performance and protective effects of the gloves meet the needs.

Nitrile gloves are widely used in the food industry because they are chemical-resistant, corrosion-resistant, anti-bacterial, flexible and comfortable, while complying with hygiene standards and food safety requirements. When using nitrile gloves, you should choose products that comply with relevant standards and specifications, and pay attention to changing gloves regularly to maintain hygiene and protective effects.

Nitrile gloves are widely used in industrial areas such as chemical handling, grease and lubricant handling, mechanical operations, electronic assembly and electrical work, cleaning and sanitary operations, etc. When selecting nitrile gloves, the selection should be based on the specific process requirements, chemical types and operating environment to ensure that the performance and protective effects of the gloves can meet the needs.

Laboratories often need to handle various chemicals, including solvents, acids, alkalis, etc. Nitrile gloves have good chemical resistance and can provide protection from chemicals that can cause irritation or damage to the operator's hands.

Nitrile gloves are widely used in the medical industry because of their good chemical resistance, antibacterial properties, softness and comfort. When using nitrile gloves, medical personnel should follow the correct method of wearing and removing gloves to ensure their effective protection and hygiene. In addition, choose the appropriate size and thickness as needed to ensure the quality and fit of the glove.

Nitrile gloves are also widely used in the field of life services, especially in cleaning work, kitchen operations, beauty and hairdressing services, pharmacies and medical assistants, pet care, etc.

-

SEMICONDUCTOR

-

FOOD

-

INDUSTRY

-

LABORATORY

-

MEDICAL

-

DOMESTIC SERVICES

Pay attention to our latest news and exhibitions

-

How do purified nitrile protective gloves achieve a design with a smooth inner layer and a friction coefficient on the outer layer?

Purified nitrile protective gloves play an important role in modern industrial, medical and laboratory environments. Their unique design - a smooth in...Read More >>> 2024-12-16

-

How to ensure complete sealing and safety of Nitrile protective gloves in the laboratory?

The laboratory is an environment full of potential hazards and chemicals, so ensuring the safety of workers is crucial. Nitrile protective gloves are ...Read More >>> 2024-12-09

-

What are the key process differences in the production of Purified Nitrile Protective Gloves compared to ordinary nitrile gloves?

Although Purified Nitrile Protective Gloves and ordinary nitrile gloves also use nitrile rubber as the main material, their production process is more...Read More >>> 2024-12-04

-

Email: [email protected]

Email: [email protected] -

Fax: +86-0510-86302212

Fax: +86-0510-86302212

-

Telephone: +86-0510-86301263

Telephone: +86-0510-86301263

-

Phone: +86-195 5190 0352

Phone: +86-195 5190 0352

Experienced staff and experts are always at your service to provide you with professional guidance for satisfactory solutions to technical problems.

-

+86-195 5190 0352

-

-

-

English

English  中文简体

中文简体